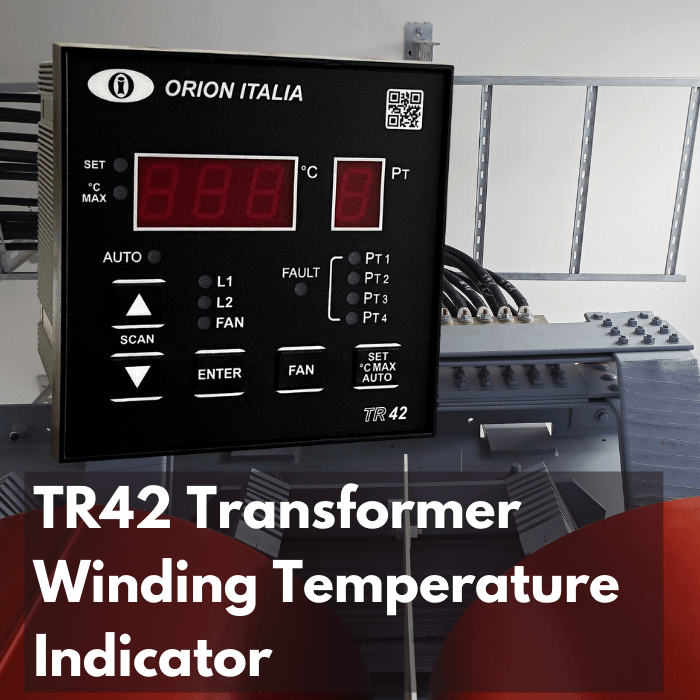

Winding Temperature Indicator/Relay for Transformers

Winding Temperature in Transformer

Transformers are one of the most important assets in an electrical system and their most important part is windings, for this reason we must measure and control the Winding Temperature in Transformers using a protection relay (integrates: settings, indicator / measurement, controller, sensor).

The windings of a transformer are the core of it, we have more than 35 years manufacturing protection relays for transformers, click below to obtain more information about our winding temperature protection relay:

Winding Temperature Relay

It is a protection relay that controls the temperature of each winding of the transformer and executes on / off commands for forced ventilation, alarm and a power breaker trip.

A winding temperature protection relay for a dry or resin type transformer is digital, based on a microprocessor or microcontroller, which allows to have many more options than the basic ones, it is possible to use its communication ports to send remote signals, integrate in everything type of computer systems, check real-time temperature values or the history of maximum and minimum temperatures stored in the protection relay.

What is Winding Temperature?, Winding Temperature Meaning

It is the internal temperature value of the transformer, the winding is the most important component of a transformer and therefore its temperature must be controlled.

The winding temperature of a transformer increases with the load, and also with the ambient temperature, overheating can be very fast and generate hot spots. The temperature of the windings must be controlled to avoid risks, and degradation of the design materials, generally in dry-type or cast resin transformers, the temperature measurement is made directly, by means of Pt100 sensors located in the windings, which measure this temperature by contact.

Winding Temperature Indicator

Once we have an installation with installed temperature sensors in each winding of a dry /cast resin transformer, we must have a device to convert those resistance variations (Pt100) into degrees values (centigrade or the standard we need), to show these values on a screen and winding temperature indicator.

Winding Temperature Gauge

The devices that measure the temperature in windings are probes or sensor, which require equipment capable of translating this measurement into a real temperature value, either an indicator or winding temperature gauge. In dry and resin transformers, Pt-100 sensor are widely used for their stability in measurement within the usual temperature ranges that a winding temperature gauge may display.

Winding Temperature Scanner

A Winding temperature scanner is a piece of equipment that measures the temperature and display degrees in a led screen, it is usually called indicator, monitor and is generally integrated with equipment that is installed to protect the transformer, such as protection relays.

A Winding temperature scanner for dry type / cast resin transform is generally based on a microprocessor (or microcontroller), that is, it is digital equipment, settings are programmed to execute actions (forced ventilation connection, alarm, trip) when the measured temperature exceeds the setting values.

Winding Temperature Indicator for Dry Type Transformer & Cast Resin

The windings of a cast resin or dry type transformer must be cared for as much as possible to keep their useful life intact, a transformer winding temperature indicator must be available to know this variable at all times and have automatic actions programmed according to the temperature. Sometimes the acronym “WTI” is used for its acronym "winding temperature indicator" these initials are often used for Oil transformers in reference to the hot spot temperature thermometer, other initials very related to this is the one associated with the "oil temperature indicator - OTI" for Oil transformers too.

Generally, the winding temperature indicator of a dry-type and cast resin transformer shows the values on a led screen, integrated in the transformer temperature protection relay.

PT100 Winding Temperature Sensor

In dry type and cast resin transformers, the most widely used winding temperature sensors are Pt100, also called: transformers winding temperature detectors. Being made of platinum, Pt100 probes have a predictable resistance response at each temperature, despite not being linear, it is always exactly the same resistance at the same temperature, offering great stability to the temperature measurement of the windings. In the case of three-phase transformers, a PT-100 sensors are installed at each winding to measure the temperature independently (prevent overheating, insulation damages due high temperature), which allows more information and a better level of protection to be available when adjusting the on or off levels of fans, alarms or even tripping. of the power breaker to avoid damage or degradation.

In the following links you will find information of interest related to Pt100 sensors for transformers and complete solutions:

- PT100 Winding Temperature Sensor

- PT100 Junction box for Temperature Protection Relay

- Dry Type Transformer Temperature Panel Board (Ready to Mount)

PT100 Winding Temperature Sensor

There are conventional temperature indicators and the new generation of digital winding temperature indicators, transformers are very important assets and must be monitored, current and temperature are the main variables to measure, in order to avoid thermal degradation, maximize the useful life and minimize power outages.

A

digital winding temperature indicator for transformer allows to know the temperature of each winding displaying locally on the led screen, they also offer the possibility of sending variables (and many others values) remotely, it is a very important advantage with respect to equipment without communication ports, since they can be integrated into local or remote control centers, automation process, SCADA, asset management systems, apps, websites, cloud systems.