Relay Used In Transformer Protection

Relay and Transformer

Transformers are the main element of an electrical installation and relays are the vital control device to work together, therefore relay and transformer are perfect electrical partners. Correct monitoring of transformer values in real time is crucial to keep them in service, feed the loads on which they depend and extend their useful life. Digital technology allows the control of the temperature of dry type (cast resin) transformers using a protection relay (ANSI 49) to prevent over temperature.

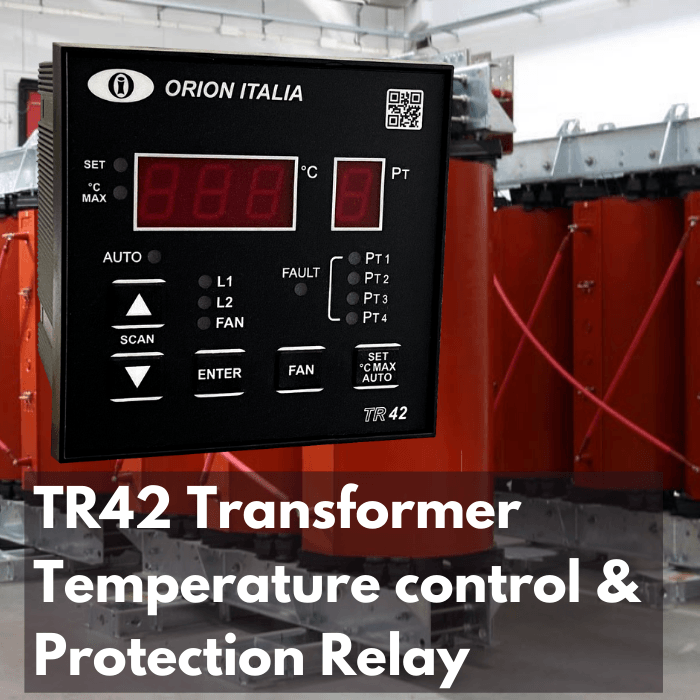

We are manufacturers of TR42 Cast Resin Transformer Protection Relay, with thousands of units installed around the world, it is very easy to install and use. Click here to get more information about this temperature control relay and download a complete manual in pdf.

Relay used in Transformer for temperature control

The relay used for temperature control in dry type (cast resin) transformers refers to electrical protection 49 (ANSI 49) function thermal image or temperature). It is a relay whose principle is very easy to understand, it constantly monitors the temperature of each windings (3-phase transformer), with this information it show alarms, send trips orders, turn off / on forced ventilation for cooling, as well as transmit information by communication ports (RS-485 / ModBus) to local SCADA systems, or any type of Cloud information (Internet). These relays can operate for any type of dry / resin transformer, of any power (KVA) or voltage level (kV), simply adjust the desired aspects in the relay programming, carry out the required wiring and you will have an electrical transformer protected by a temperature relay.

Transformer Protection Relay Price

The mandatory electrical device associated with a power transformer is the protection relay, there are transformers for all kinds of uses: auxiliary services, generation, transformation, transportation. Usually dry type / cast resin transformers are installed for auxiliary services in large industries, electrical supply of companies, shopping centers, residential use, hotels or any medium-sized installation. The protection relays for dry type transformers are digital (based on programming and microprocessors) due to their high speed response, low cost and high reliability, in addition to the extras such as connection to external computer systems through communication ports, and incorporation not only of the basic protection functions, but also control functions for a better use of these relays at a low price. The price of a temperature protection relay for a transformer will depend on the functions it has, as well as the communication possibilities, digital inputs and outputs, the TR42 has a low price in relation to the technical characteristics it has.

How to Protect Transformer

To protect transformers there are many methods according the transformer technology (in this case we will focus on the dry type – cast resin), the most important aspects to protect a transformer are:

1.- Voltage (over voltage, under voltage): Due to the fact that very high values can influence the degradation of the insulation of the windings, in addition, high or low voltage variations must be kept within an operating range to supply the loads with correct values. A voltage control relay is usually used for this.

2.- Current: The overcurrent and instantaneous overcurrent (short circuit) must be detected to prevent irreversible internal damage to the transformer. An overcurrent protection relay is usually used for this.

3.- Temperature: This value can increase or decrease by the ambient temperature, connected load (power) and internal characteristics in the core, windings or connections, the control will be done with a protection relay, which has inputs that are measuring in real time the temperatures of the windings and execute commands according to the programming, such as alarm, trip, on / off of cooling fans.

Transformer Relay

A transformer relay is a protection device conceive to digitally measure the cast resin (dry type) electrical and physical variables such as currents, harmonics and temperatures that are crucial to transformer mechanical integrity. This devices could also control the transformer ventilation (FAN) to maintain a good working temperature, or they could instantly remove the power supply depending on current levels and over temperatures.

Digital Relay used in Transformer Temperature Protection

Over the years, technology has improved everything, protection relays included, currently we have digital temperature protection relays for transformer protection, based on microprocessors, with led display, communication ports, inputs and digital outputs, with data storage capacity and internal programming to customize the actions it executes, these digital protection relays launch commands in real time with actual temperature values read from sensors directly connected to the transformer (true metering values). The capabilities of these devices have improved over time. Currently it is a very sophisticated technology, made to improve the electrical sector, more safety for electrical installations and human operators and extend the useful life of these transformers by preventing their operation under conditions outside those recommended by the manufacturer.

Transformer Protection

A power transformer is a very expensive machine, therefore it must be protected as much as possible, the higher power and more important it is, more protections devices are associated with it, the following list includes transformer protections for an Oil model (in the case of the dry type, it is less power, only some of them apply).

Diferencial: Actually compares between primary current and secondary current of power transformer, if any current unbalance occurs a Trip signal will actuate

Overcurrent: Any currents above threshold and time will generate a Trip.

Overvoltage: To protect the transformer from overvoltage at power frequency or of atmospheric origin, adequate surge arresters must

be installed.

Restricted Earth Fault (REF): is the unintended fault between the live conductor and the earth. REF protection is fast and can isolate winding faults extremely quickly, thereby limiting damage and consequent repair costs.

Buchholz: Gases moving in the direction of the oil conservator or shock waves created by the rapid gas development trigger the signaling system of the Buchholz relay.

Tank Earth: Overcurrent protection from currents flowing from the tank frame to ground.

Overfluxing: The magnetic flux density in windings is directly proportional to the induced voltage and inversely proportional to the frequency. Protection system operates when this ratio increases above normal level

Thermal: based on the measure of the current and on the thermal time constant of the transformer or by direct temperature metering of the coils.

Type of Transformer Protection Relays

There is a wide range of Transformer Protection Relay according to the type of transformers and its power. Ansi 49 Temperature protection relay, Ansi 50 Short time overcurrent protection, Ansi 51 Long time overcurrent protection, Ansi 87 T Differential Protection of Transformer. Earth Fault Protection (Restricted). Ansi 80 Buchholz Relay - Gas Detection-. Dissolved Gas and Moisture Monitors, Bushing Monitors ANSI 26 – Apparatus Thermal Device. ANSI 24 Over-excitation Relay